Side gating

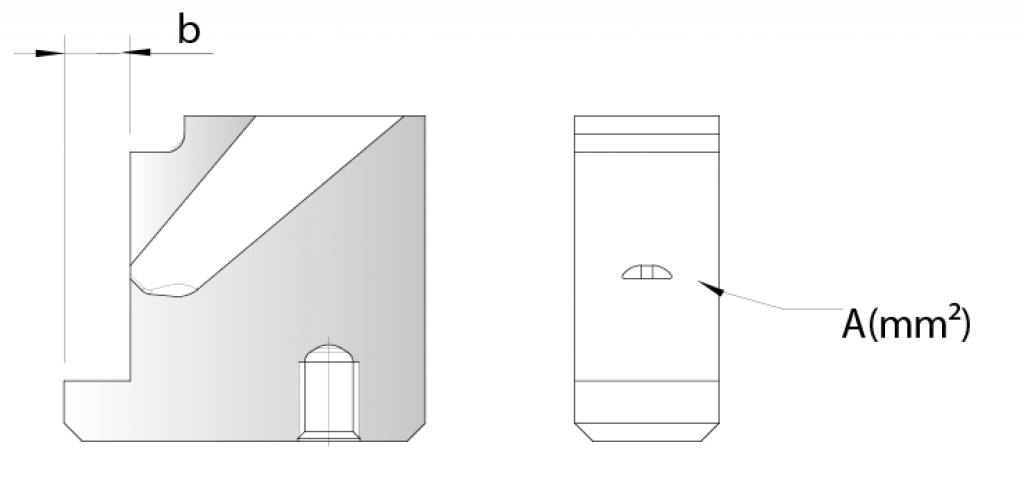

Straight standard sub-gate for side-gating

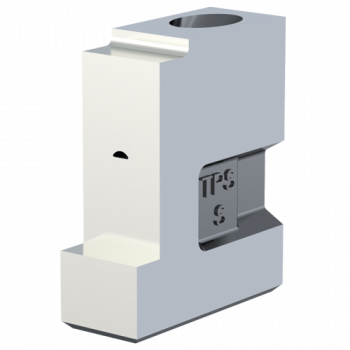

SIDE GATING TPS

Gate inserts - TPS

- straight standard sub-gate for side-gating

- integrated dead-end recess reduces loss of pressure and shear stress

- highly wear-resistant hot working steel M2 (1.3343) – 54+2 HRC

side gating TPS

Sizes / Shot weights

The chart shows the shot weights which can be reached with the respective sizes depending on the viscosity of the plastic materials used.

| TPS-S | TPS-1 | TPS-2 | TPS-3 | |

|---|---|---|---|---|

| Name | TPS-S | TPS-1 | TPS-2 | TPS-3 |

| Anschnitt | 0.4 -0.8 | 0.8 - 1.8 | 0.8 - 2.8 | 1.1 - 4.5 |

| NV* | 30 | 120 | 600 | 1800 |

| MV* | 20 | 75 | 350 | 1000 |

| HV* | 12 | 50 | 175 | 600 |

* max. shot weights (g) | NV: low viscosity | MV: medium viscosity | HV: high viscosity

side gating TPS

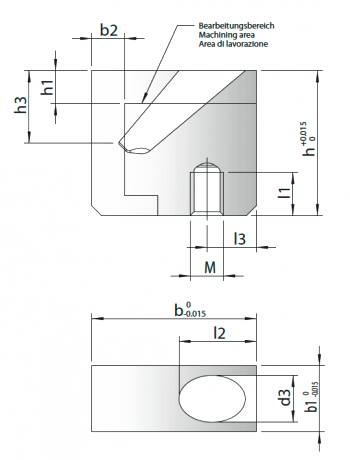

TPS Details

| b | b1 | b2 max. | d3 | h | h1 max. | h3 | l1 | l2 | l3 | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TPS-S | TPS-S | 15 | 6 | 2.4 | 4 | 18 | 4 | ~7 | 6 | 7.1 | 5.5 | 4 |

| TPS-1 | TPS-1 | 18 | 8 | 2.6 | 6 | 22 | 5 | ~9 | 6 | 8.4 | 6 | 4 |

| TPS-2 | TPS-2 | 25 | 10 | 5 | 8 | 22 | 6 | ~11 | 6 | 11.8 | 7.5 | 5 |

| TPS-3 | TPS-3 | 30 | 12 | 6.5 | 10 | 27 | 7 | ~13 | 6 | 14.1 | 8 | 5 |

side gating TPS

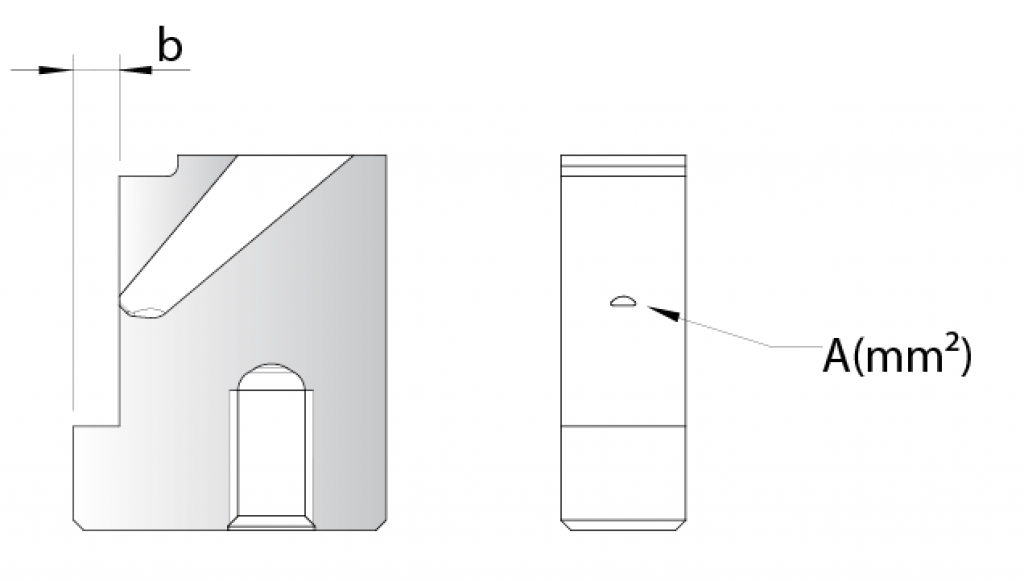

TPS-S

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.12 | 0.4 | 2.1 |

| 2 | 0.40 | 0.7 | 2.2 |

| 3 | 0.75 | 1.0 | 2.3 |

| 4 | 1.13 | 1.2 | 2.4 |

side gating TPS

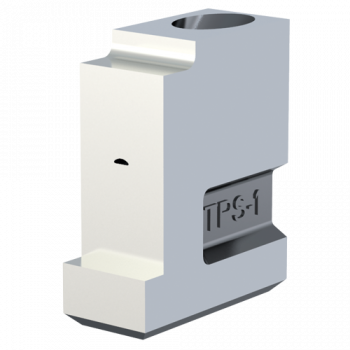

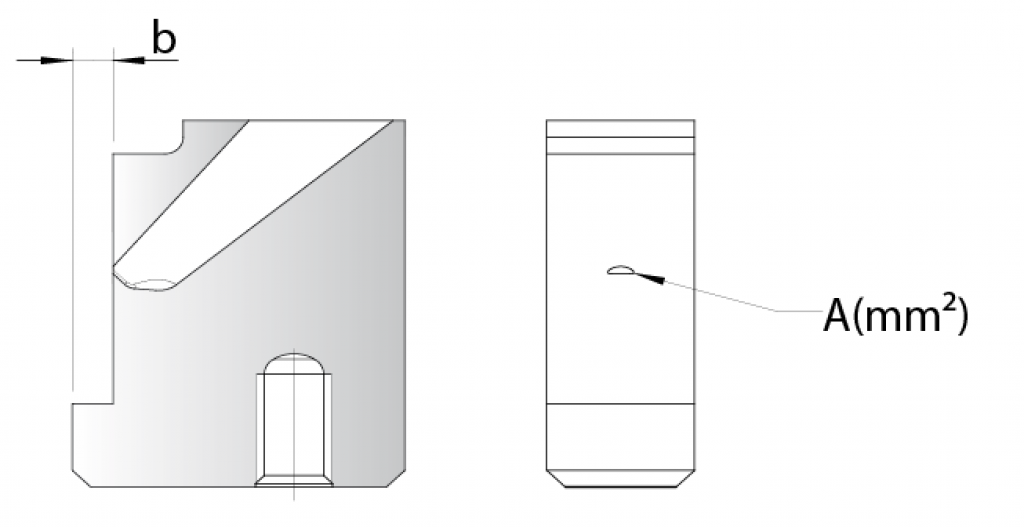

TPS-1

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.49 | 0.8 | 2.2 |

| 2 | 0.92 | 1.1 | 2.3 |

| 3 | 1.42 | 1.4 | 2.4 |

| 4 | 1.97 | 1.6 | 2.5 |

| 5 | 2.56 | 1.8 | 2.6 |

side gating TPS

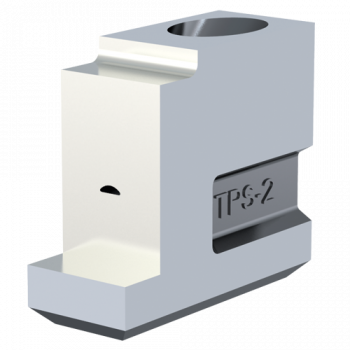

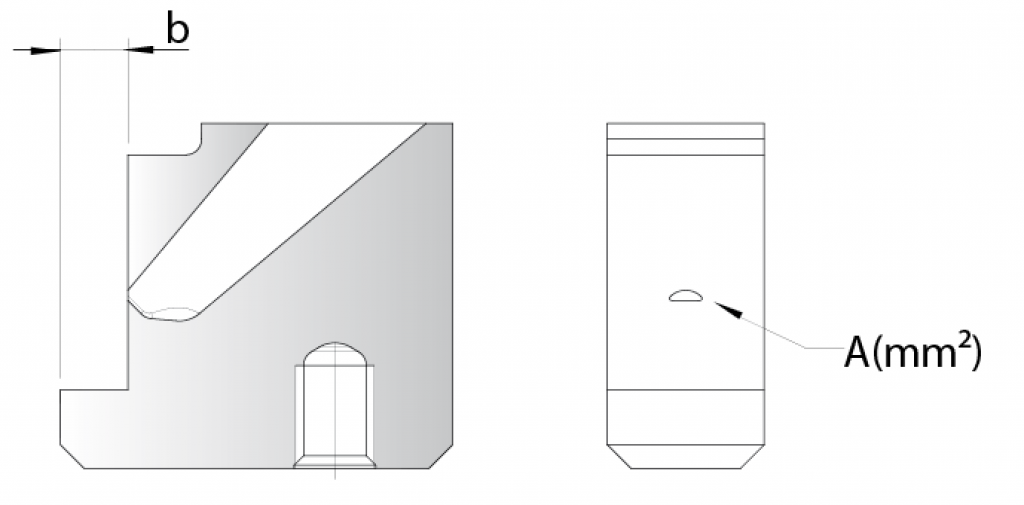

TPS-2

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 0.54 | 0.8 | 4.2 |

| 2 | 1.05 | 1.2 | 4.3 |

| 3 | 1.64 | 1.5 | 4.4 |

| 4 | 2.3 | 1.7 | 4.5 |

| 5 | 3.0 | 1.9 | 4.6 |

| 6 | 3.76 | 2.2 | 4.7 |

| 7 | 4.55 | 2.4 | 4.8 |

| 8 | 5.37 | 2.6 | 4.9 |

| 9 | 6.23 | 2.8 | 5.0 |

side gating TPS

TPS-3

| A [mm²] | ~ Ø [mm] | b2 [mm] | |

|---|---|---|---|

| 1 | 1.0 | 1.1 | 5.2 |

| 2 | 1.81 | 1.5 | 5.3 |

| 3 | 2.7 | 1.9 | 5.4 |

| 4 | 3.67 | 2.2 | 5.5 |

| 5 | 4.7 | 2.4 | 5.6 |

| 6 | 5.78 | 2.7 | 5.7 |

| 7 | 6.92 | 3.0 | 5.8 |

| 8 | 8.09 | 3.2 | 5.9 |

| 9 | 9.3 | 3.4 | 6.0 |

| 10 | max. 15.8 | 4.5 | 6.5 |

side gating TPS

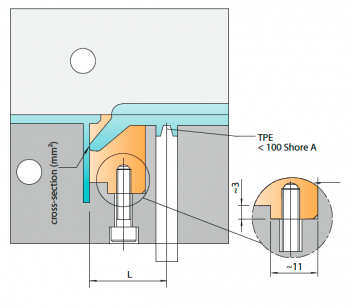

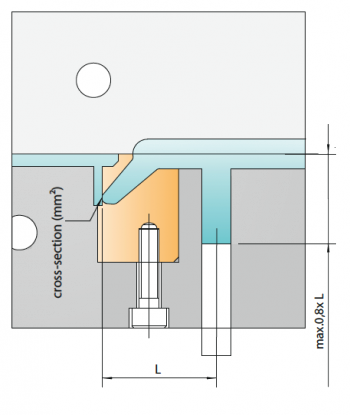

Distance to ejector

- low shore hardness = shorter distance L

- use centring pin

- max. hardness 100 Shore A

Table for distance L

| flexible Materialien | steife Materialien | ||

|---|---|---|---|

| SGC-S | SGC-S | ~ 18 | ~ 23 |

| SGC-1 | SGC-1 | ~ 22 | ~ 30 |

| SGC-2 | SGC-2 | ~ 28 | ~ 38 |

| SGC-3 | SGC-3 | ~ 33 | ~ 47 |

side gating TPS

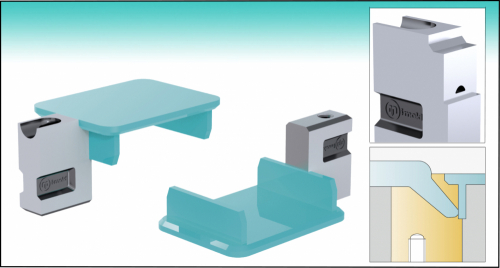

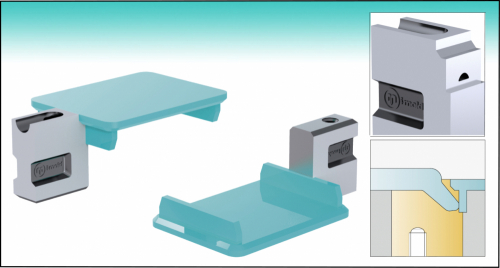

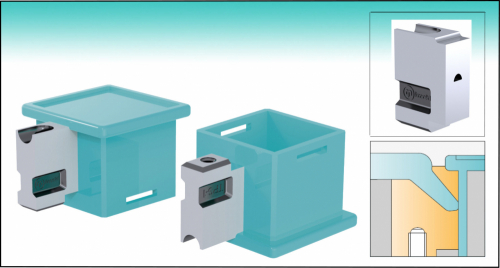

Examples of installation

Side gating - standard installation

Side gating - for flat contours

Side gating - for flat contours

Downloads

Further documents

Your contact persons for this product are: